Whatever happened to this blog? Did the new CNC machine mentioned in the previous post ever arrive? Why even start a blog if you’re not going to update it regularly? Do you have pictures of the new machine? Read on to find out the answers to these and other questions in this second instalment of the Phobos Foundry blog.

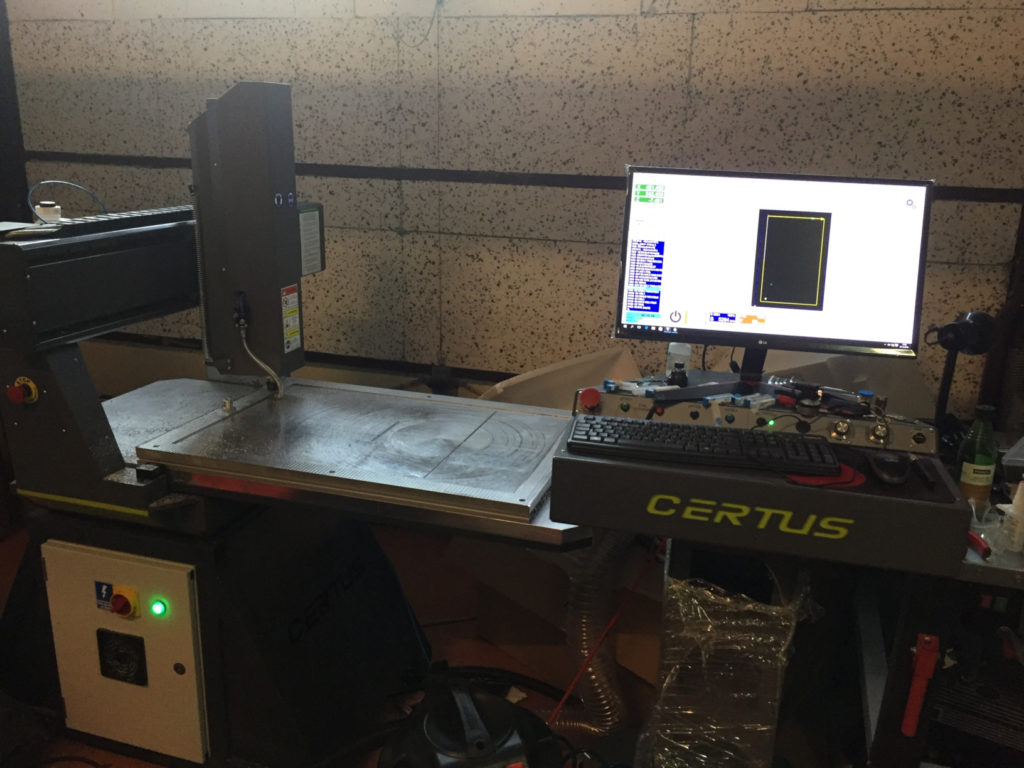

Originally, this blog post went into details about my new Certus 6090 Servo CNC router which has proven its merit in production. It’s fast and has a large work envelope, which more than covers for its lack of stiffness and power since I’m using it for plastics. It also lacks precision when compared to an actual mill, but the build quality is what you get for the price.

The definite pluses also include the free-standing control panel on wheels, which houses a nice, low-budget PC that boots really fast and runs the CNC controller without issues. There could be more room for the mouse, and the control knobs are more of an annoyance than a feature for me since they tend to bump into the keyboard and mouse cables, changing spindle speed values seemingly at random.

I sort of regret this being on lease because it means I can’t mod it without going against my agreement with the bank. It would be great if I could switch between a normal milling spindle and a laser for engraving. Engraving finished products is something I’ve dreamed of for a long time, but when engraving with an endmill you have to hold on to your part without damaging it and that’s really hard in my current workflow. Lasers fix the issue since they don’t touch the part or exert any forces that might move it, so a gentle clamp is enough to have good looking pictures and logos on you parts. But I’m getting off-topic here.

Overall, the Certus router is an okay buy for my use, cheap but decent and makes short work of any orders, especially after attaching a chip extractor. It absolutely blows when cutting metal, because there are no covers, using the integrated mist cooler system sprays toxic fumes and chips all over the place. It puts me off from redoing a vacuum table that I made for it, which currently doesn’t work and needs a redesign.

After completing all the past orders and getting back to my normal production workflow, I decided it was time to take another look at the Maho. I had a few ideas of what might have happened to it, and what the fixes would entail, so I went ahead and did some testing. Here comes the “fun” part: diagnosing the machine, it occurred to me to change a parameter in the settings file (just a text file with a different extension that stores machine parameters in LinuxCNC), which immediately fixed the problem. It took about 15 minutes.

There are many words that come to mind in such situations, but the Internet has provided us all with images that convey certain emotions swiftly and in an entertainingly familiar way:

I hope you all had a very Merry Christmas and I wish everyone a great 2020!